Machine Learning in Industrial Robotics

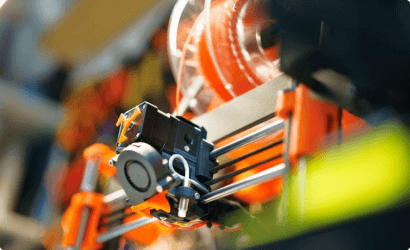

Machine learning is transforming industrial robotics by enabling robots to learn from data and continuously improve their performance. Unlike traditional programming, where robots execute predefined tasks, machine learning allows them to analyze patterns, adapt to changing conditions, and optimize operations.

One of the primary applications of machine learning in industrial robotics is predictive maintenance. By analyzing sensor data and historical performance, AI-powered robots can predict when a machine component is likely to fail. This proactive approach minimizes downtime and reduces maintenance costs by allowing companies to perform maintenance only when necessary, rather than following fixed schedules.

Another significant advantage of machine learning in robotics is defect detection. In manufacturing, AI-driven robots compare real-time images of products against a database of defect-free models. If a deviation is detected, the system flags the defective product for removal or correction. This automated quality control process eliminates human error, enhances product consistency, and reduces waste.

Furthermore, machine learning enables robots to optimize assembly line processes by identifying inefficiencies and suggesting improvements. AI algorithms analyze workflow data and adjust robotic movements for increased speed and precision. This is particularly beneficial in industries such as automotive manufacturing, where production speed and accuracy are critical.