AI in Supply Chain and Production Line Optimization

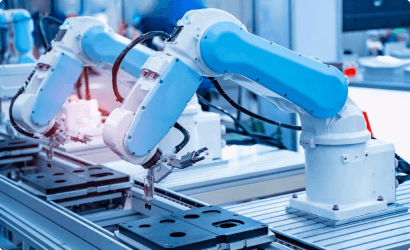

AI in industrial robotics is playing a crucial role in optimizing supply chain management and improving production line efficiency. AI-powered robots and automation systems help manufacturers streamline logistics, reduce bottlenecks, and increase productivity.

One of the key applications is real-time demand forecasting. AI analyzes historical sales data, market trends, and production capacity to predict future demand with high accuracy. This allows manufacturers to adjust production schedules, minimize overproduction, and prevent inventory shortages. By optimizing resource allocation, companies can significantly reduce costs and waste.

Another major advantage is AI-driven warehouse automation. Autonomous robotic systems powered by AI manage inventory, retrieve items, and transport materials across warehouse facilities. These robots use computer vision and LiDAR sensors to navigate safely and efficiently, reducing human labor requirements while increasing operational speed. AI also enables automated sorting and packaging systems, which classify products based on size, weight, and destination, improving logistics and order fulfillment accuracy.

AI-powered robotic process automation (RPA) is also transforming industrial supply chains by automating repetitive administrative tasks such as order processing, shipment tracking, and supplier communication. This reduces human error and enhances overall efficiency.

On production lines, AI optimizes workflow by detecting inefficiencies and adjusting robotic movements for better precision and speed. AI-powered systems monitor machine performance in real-time, adjusting speed, pressure, and energy consumption based on workload demands. This ensures a continuous and highly efficient production cycle with minimal downtime.

By integrating AI into supply chain management and production line operations, industries can achieve greater efficiency, lower costs, and higher product quality. AI-driven automation ensures that manufacturing facilities can respond to market demands quickly and maintain seamless operations without unnecessary delays or disruptions.